WRF

System utilised to eliminate firing and calibre defects

generated by the kiln; how this may easily be understood by

evaluating the data-feed on the screens, this system was

conceived to reduce the difference in calibre by up to an

average 0.1 /0.3 mm on each tampon of kiln section with the

undoubted financial returns that this standard produces:

The WRF can be installed on any type of kiln and in nearly all

the cases, installation is also possible on kilns in function,

taking a period of about 3 days, plus another 2 days to carry

out controls, adjustments and for the instruction of your

staff.

We shall now pass on to illustrate graphically the advantages

that can be obtained through the installation of a WRF system.

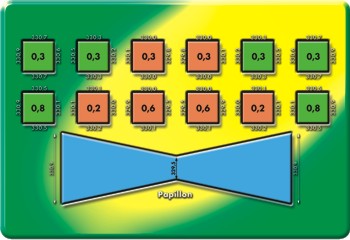

In table 1 the measurements are shown of a tile tampon obtained

by using a kiln of the

latest design.

As may be seen, production is optimum

dealing as it does with a first production

choice but with 2 different

calibres.

In reality we often find less optimum situations and in fact

sometimes the calibre may be as much as 2mm.

Table 1

State of the production fired with

a normal installation, before the introduction of the WRF

system.

Quality of the production: first choice from kiln 100%

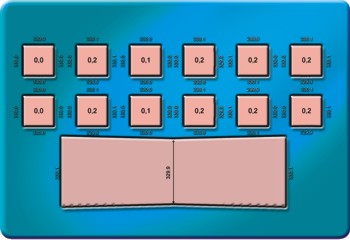

Table 2

The following table illustrates the production quality relative

to calibre defect after the installation of the WRF on the

identical kiln of the previous example.

State of the production after installation of the WRF system

control.

Production quality:1st choice from kiln 100% kiln

ONE SOLE CALIBRE

|